1. Carbon Captured Storage. Learn How Total CO₂ Captured (Tonnes per Year) is Actually Measured?

Act2Vision Industrial Carbon Management Series – Blogpost 5

One of the most common questions about Carbon Capture and Storage (CCS) is deceptively simple: How do you actually measure how much CO₂ is captured each year? “Total CO₂ captured (tonnes per year)” is not a model output or an assumption. It is a measured, regulated and auditable quantity, based on industrial-grade devices that are already standard in emissions reporting and process industries. In this blogpost, I explain how total CO₂ captured is measured in practice, which devices and gauges are used, and how raw sensor data becomes a verified annual figure used for EU ETS, funding and climate reporting.

2. Why Measuring Total CO₂ Captured Matters

Accurate capture measurement is the foundation of CCS credibility. This is why CCS capture measurement relies on established industrial instrumentation, not novel or experimental tools, because without reliable data:

- CO₂ cannot be counted as “not emitted” under the EU ETS,

- Transport and storage contracts cannot be settled,

- Climate impact claims cannot be verified,

- Investors and regulators cannot assess performance.

3. Measuring CO₂ Capture Is a System, Not a Single Device

There is no single meter that directly outputs “tonnes of CO₂ captured per year”. Instead, capture measurement relies on a measurement system, combining, gas concentration analysis, gas flow measurement, mass balance calculations and product stream metering after capture. And each of these four element plays a specific role.

3.1 Measurement Equipment

| Purpose | Where installed | What is measured | Common technologies used | Why this matters | |

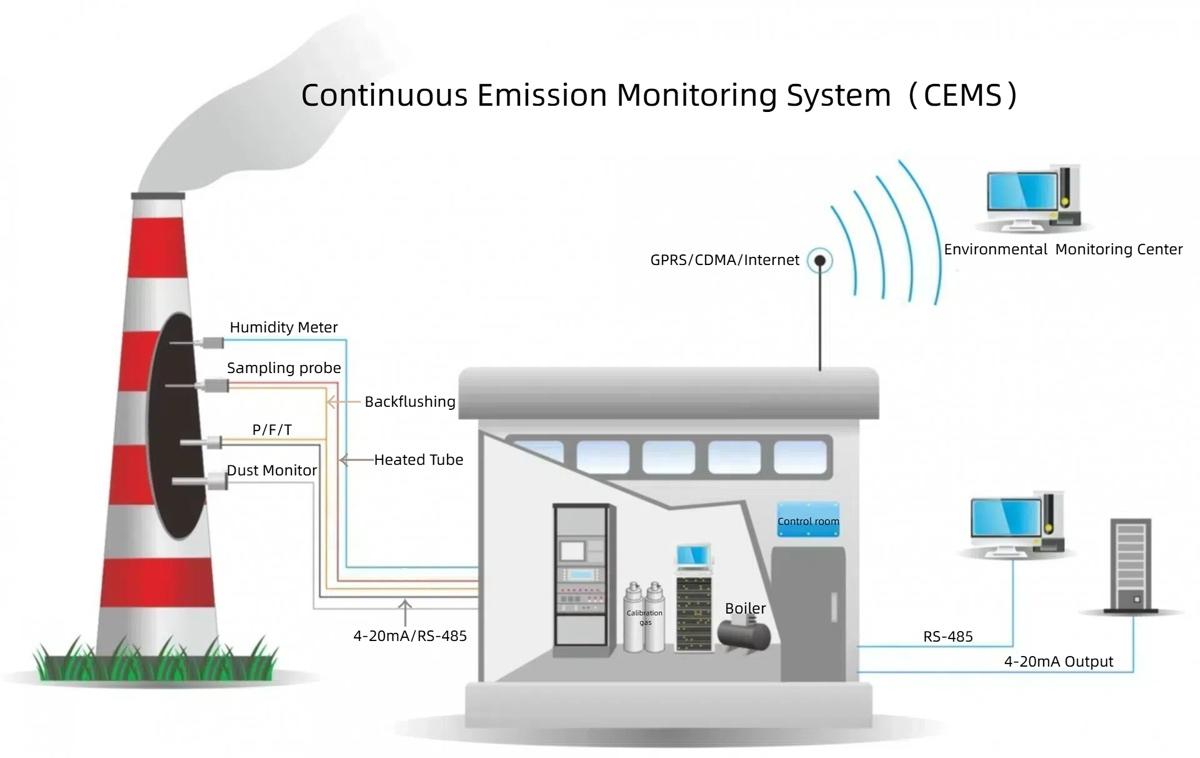

Continuous Emissions Monitoring Systems (CEMS) |

Measure CO₂ concentration in gas streams | Upstream of the capture unit (before capture)

Downstream or at the vent stack (after capture) |

CO₂ concentration (% or ppm)

Oxygen (O₂) concentration (for correction) Sometimes NOx, SO₂ and moisture |

Non-dispersive infrared (NDIR) analysers

Fourier-transform infrared (FTIR) analysers Paramagnetic oxygen analysers |

CEMS provide continuous, high-frequency data and are already accepted under EU ETS monitoring plans. They show how much CO₂ is present in the flue gas before and after capture. |

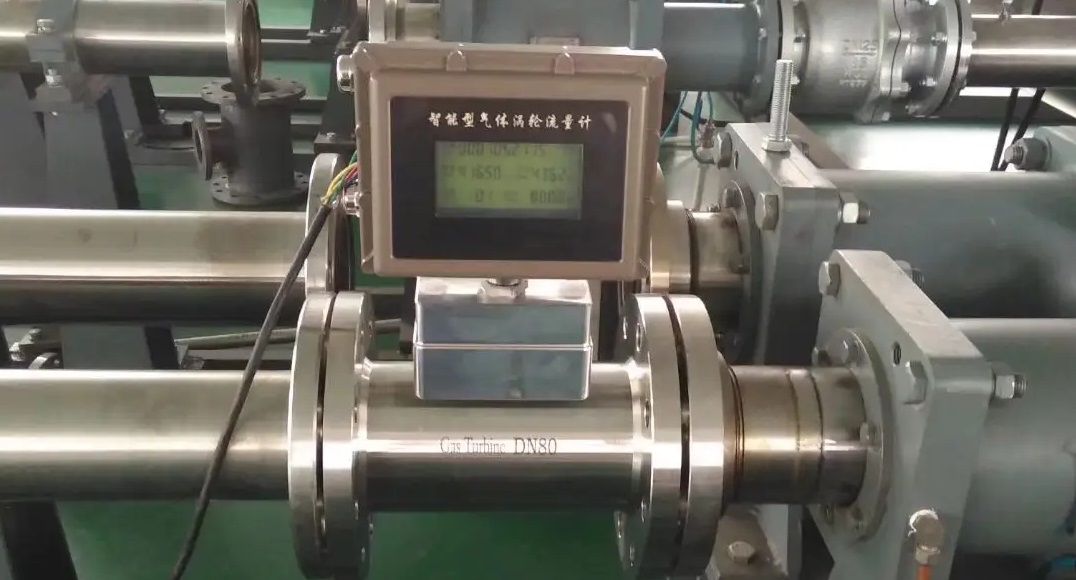

| Flue Gas Flow Meters | Measure how much gas flows through the system | In flue gas ducts upstream and downstream of capture | Gas flow rate (Nm³/h) | Ultrasonic flow meters (most common for large ducts)

Differential pressure systems (e.g. Pitot tubes) Thermal mass flow meters (for smaller streams) |

CO₂ concentration alone is meaningless without knowing how much gas is flowing. Flow rate × CO₂ concentration = CO₂ mass flow. |

3.2 Mass Balance: The Core CalculationThe key calculation for total CO₂ captured is a mass balance. In simple terms:

CO₂ captured = CO₂ entering the capture unit − CO₂ leaving the system

Each term is calculated using CO₂ concentration (from CEMS), Gas flow rate (from flow meters) during the Operating hours of the facility. This approach is required under EU ETS methodologies, technology-neutral, and auditable and reproducible. It also ensures that capture performance reflects real operating conditions, not design values.

4. Measuring the Captured CO₂ Product Stream

Once CO₂ is separated and compressed, it becomes a CO₂ product stream. From this point, it is treated like any other industrial gas. The key devices used are:

-

Source: Endress+Hauser Proline. Coriolis stromingsmeter (2025) Coriolis mass flow meters

-

- Measure mass flow directly (t/h)

- High accuracy

- Common at compressor outlets

-

- Pressure, temperature and density sensors (examples / IoT – use internet).

-

- Used together to calculate mass flow

- Standard in pipelines and terminals

-

- Gas composition analysers (examples / IoT- use internet).

-

- Measure CO₂ purity

- Detect impurities such as O₂, N₂ and water

-

These product stream measurements define how much CO₂ is actually transferred to transport and storage operators, and often forms the contractual and regulatory point of reference.

5. Calibration, Verification and Data Quality

Measurement devices are only credible if they are properly maintained. To ensures that annual capture figures are defensible, transparent and compliant, standard practices (protocols) are used for:

- Regular calibration using certified reference gases,

- Identification of redundant or defect sensors for critical measurements,

- Checking data for validation and consistency,

- ETS verification.

Calibration of measurement devices is done by Independent third-parties.

6. What Number Is Reported as “Total CO₂ Captured”?

In practice, two numbers often exist. First is Gross CO₂ captured, measured at the capture unit outlet. Second, the Net CO₂ captured and transferred, measured after compression and conditioning. Net CO₂ captured is usually the most relevant number for climate accounting and CCS system planning, because it reflects what can actually be transported and stored (read blogpost 4 on how to measure real climate impact).

7. Key Takeaways

- Total CO₂ captured is a measured quantity, not an estimate

- Measurement relies on CEMS, flow meters and mass balance calculations

- Captured CO₂ is tracked as a product stream after separation

- Calibration and verification are essential for credibility

- Reliable capture measurement underpins the entire CCS value chain

Building process clarity today for the value chain of tomorrow.

Maarten van Oost@act2vision.nl | +31 (0) 686 698 026 | Amsterdam, Netherlands, EEA

- Blogpost #1: What is CO₂ and why is it a problem and a value chain?

- Blogpost #2: What Is Carbon Capture and Storage (CCS)? The Complete 2025 Value Chain Explained.

- Blogpost #3: CCUS for Waste-to-Energy: Why Carbon Capture at WtE Plants Matters for Europe’s Net-Zero System

- Blogpost #4: Carbon Capture and Storage: How to Measure Real Climate Impact?