The best way to start a Supply Chain Digital Twin Strategy. Starting up a project?

My blogpost provide how Supply Chain Digital Twin Strategies (SCDTS) integrate artificial intelligence (AI), Internet of Things (IoT) and advanced analytics to transform traditional supply chains. Analyzing supply‑chain functions, the report highlights main cost drivers and explains how digital twins can reduce these costs .

My blogpost examines the interaction between IoT and AI; step‑by‑step I present a roadmap for adopting SCDTS, covering strategic scoping, and a list of leading vendors. The conclusion underscores that Supply Chain Digital Twin Strategy offers end‑to‑end visibility, resilience and sustainability, moving supply chains from unknown uncertainty to managed variability.

Download the whitepaper (Supply_Chain_Digital_Twin_Strategy (II) v1.0)

Interplay between IoT data and AI‑driven analytics

The digital twin “body” provides the contextual model of the supply chain, while artificial intelligence is the “brain” that interprets data and recommends actions. The digital twin is a data‑driven digital replica of a physical system; and AI can be embedded within a digital twin to enable predictive maintenance, automated scenario testing and anomaly detection. The use of IoT-sensors and cloud services support the collection, streaming data from assets, pallets, vehicles and production lines; the data is stored in data lakes or cloud platforms (e.g., AWS, Azure). AI algorithms (machine learning, deep learning and reinforcement learning) process the data to forecast demand, detect anomalies and optimize decisions.

For example:

- Data acquisition & integration. IoT sensors generate real‑time data on equipment conditions, location, temperature and utilization. This data is ingested into cloud platforms through messaging protocols (e.g., MQTT, HTTPS) and integrated with enterprise systems (ERP, MES, WMS). Building a digital twin requires access to real‑time or historical data and integration into SCADA, ERP or MES systems.

- Analytics and AI. AI techniques such as probabilistic forecasting predict demand and supply variability, optimizing buffer levels. Predictive maintenance models use time‑series data to predict equipment failures and schedule repairs. Deep learning models can analyze images or sensor data to detect quality issues. Reinforcement learning algorithms can learn optimal policies for dynamic routing and load balancing.

- Simulation and optimization. Simulation engines model interactions among supply‑chain entities. DSCTs captures interactions through transactions (purchase orders, shipments) and adapt to evolving supply chain structures. Optimization algorithms (linear programming, heuristics, meta‑heuristics) search for feasible solutions and trade‑offs across cost, service and sustainability. Virtual twin solutions allow comparison of cost vs. sustainability scenarios.

- Visualization & decision support. Results are presented through dashboards, maps and KPI reports. Digital twin offers custom triggers and alerts for abnormal conditions. Secure components of digital twins can be shared with suppliers and partners, creating collaborative ecosystems with continuous realignment and AI‑driven workflows.

Download the whitepaper (Supply_Chain_Digital_Twin_Strategy (II) v1.0)

Supply‑chain functions & cost breakdown

“Digital twin Supply Chain Strategy move supply chains

from unknown uncertainty to known variability and support probabilistic planning”

Supply chains typically include inbound logistics, warehousing & handling, inventory management, packaging, planning & control, outbound logistics and last‑mile delivery.

- Research on value‑added logistics (VAL/VAS) shows typical cost contributions: Warehousing & inbound logistics 15–20 %,

- CDC (central distribution center) handling and labor 15–18 %,

- CDC housing ~15 %, inventory 12–20 % (depending on product value density),

- planning & control 5–8 %,

- packaging 2 %.

- outbound logistics 25–30 %.

Although these numbers vary by industry, they underscore that warehousing, labour and outbound logistics are major cost drivers. Note that costs of customer returns, damaged goods, obsoletes, unsalable and slow-moving stock should also be taken into account (as might other cost drivers in your specific area of business).

Download the whitepaper (Supply_Chain_Digital_Twin_Strategy (II) v1.0)

Digital twins bring value across all functions

- Inbound & transportation – Virtual twins map inbound flows, track shipments via IoT sensors and anticipate delays. Virtual twins allow companies to gather real‑time production information from suppliers and sensors in the field, predict arrival times and even monitor containers and refrigeration units. They support proactive actions when trucks are late or equipment fails.

- Warehousing & handling – Warehousing labor can effect operating cost significantly. Digital twins simulate warehouse layouts, test routing and reduce transportation costs. They help plan labour and minimize space waste by identifying bottlenecks.

- Inventory & buffer management – Twins monitor inventory levels in real time using IoT sensors and RFID tags. Virtual twin uses AI‑based probabilistic forecasts to improve planning and dynamic buffer allocation, resulting in improvements in forecast accuracy and reductions in delays and downtime. They help determine safety‑stock positions and trade‑offs between cost and service.

- Packaging & value‑added services – Handling and Packaging operations are simulated to optimize line setups and reduce waste. Digital twins are used to cut energy consumption and waste.

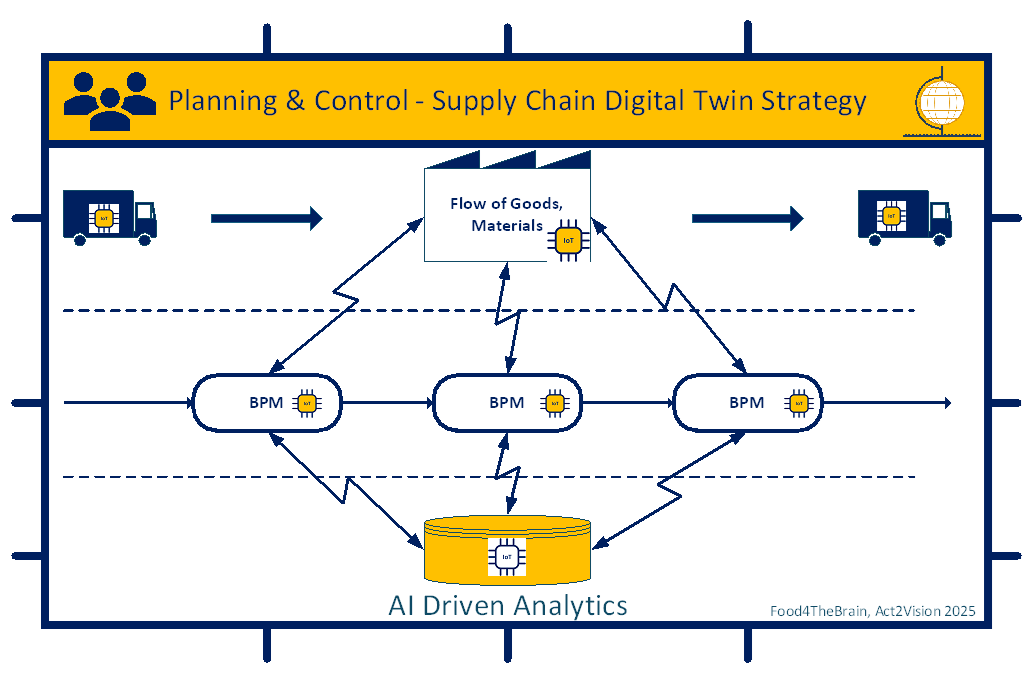

- Planning & control – Digital twins unify data from ERP, MES, WMS and IoT sensors for real‑time planning. They enable scenario‑based planning and scheduling, adjusting production and logistics based on predicted demand and capacity. Dynamic planning with digital twins can improve fulfillment and reduce labor cost.

- Outbound logistics & last‑mile – Twins optimize routes, fleet utilization and last‑mile delivery. Real‑time alerts provide for abnormal situations and uses custom triggers to reroute shipments. Materialize’s case studies show dynamic route planning improved on‑time delivery and reduced delays.

- Predictive planning and preventive maintenance. Digital twins transform planning from reactive to predictive. AI‑enabled virtual twins provide probabilistic forecasts that allocate buffers dynamically and cut downtime. Component and asset twins monitor equipment health and detect wear, allowing predictive maintenance and reducing unplanned downtime. You can use Digital twins to reduce downtime.

- Workflow monitoring and pro‑active control. Creating digital twin models of supply chain networks enables real‑time operational modeling and monitoring. Actionable intelligence anticipates problem scenarios, incorporates ground‑truth data and automates responses. Deep data intelligence within digital twins allows organizations to monitor all assets—from containers and pallets down to vials—overcoming organizational silos and enabling partners to identify deviations and fix them quickly. Networks of digital twins support collaboration and continuous realignment across the ecosystem; AI/Machine Learning (ML) scripts drive predictive intelligence and automate workflows.

- Flexibility and reduced bottlenecks. Process twins replicate entire operations, allowing simulation of layout changes and testing of “what‑if” scenarios without interrupting the real process. In warehouses and logistics, digital twins visualize bottlenecks before they happen and make operations more agile and efficient. Virtual twins, decision‑makers can run simulations to stress‑test the supply network and plan for disruptions.

- Resilience and risk management. Supply chain disruptions (pandemic, geopolitical events, Suez Canal blockage) expose fragility. Virtual twins provide visibility into events that might affect suppliers, giving stakeholders the power to predict and avoid disruptions. Supply chain digital twins require IoT sensors beyond manufacturing walls and into warehouses and suppliers, enabling real‑time visibility of transit times and inventory. The ability to run scenario simulations helps companies prepare contingency plans and stress‑test their supply chains.

- Sustainability and circularity. Combining virtual twins of product, sourcing supply chain and manufacturing can enable new value chains and optimize material flow. Supply‑chain twin balances cost, sustainability and carbon emissions by comparing multiple scenarios. Virtual twins also underpin recycling and reuse strategies by tracing critical materials across their lifecycle and enhancing circularity

Download the whitepaper (Supply_Chain_Digital_Twin_Strategy (II) v1.0)

What are we actually talking about?

Exactly, Artificial Intelligence (AI). Humans (intelligence) have an idea and know how to shape and implement ideas with AI by asking questions, giving assignments and finding opportunities.

Digital Twin Supply Chains is the next development (emerging) of data-driven operations. DTSC integrates real-time monitoring, analysis, and simulation to create adaptive, resilient, and efficient supply chains. In my opionion, supply chains with limited capacity (bunkers, warehouses) with frequent deliveries, aligned with production capacity (Inbound & Operations Planning & Control = Control Tower) can benefit from DTSC.

Organizations should start by developing a clear BPM foundation, invest in a standardized data infrastructure, and gradually integrate AI-driven optimization models. Starting pilot projects ensures scalability and organizational learning, paving the way for full implementation of digital twins.

Download the whitepaper (Supply_Chain_Digital_Twin_Strategy (II) v1.0)

Get in touch. Interested in innovations and integrated field projects for your organization? We explore, plan and implement together.

Food4TheBrAIn, Act2Vision.