What Is Carbon Capture and Storage (CCS)? The Complete 2025 Value Chain Explained

Part 2 of the Act2Vision Industrial Carbon Management Series

Carbon Capture and Storage (CCS), often expanded to Carbon Capture, Utilisation and Storage (CCUS), is rapidly shifting from a niche technology to a core pillar of global decarbonisation. With new commitments announced at COP30 in Brazil, governments and industries are being pushed to accelerate CO₂-reduction, phase down fossil fuels, and develop open-access CO₂ transport and storage networks.

In this article, we explain what CCS is, how the value chain works, and why the latest global climate decisions make CCS an essential component of Europe’s industrial transition.

1. COP30 (Brazil): CO₂ Reduction and the Global Push to Build CCS Systems

During COP30 in Belém, Brazil november 2025, world leaders reinforced the urgency of cutting global CO₂ emissions before 2030. Key outcomes included:

- A renewed global goal to reduce emissions by 43% by 2030, in line with the IPCC 1.5°C trajectory.

- Accelerated phase-down of unabated fossil fuels, with clear calls for replacing them with renewables and low-carbon industrial processes.

- A commitment to scale carbon management, including CCS, CCUS and carbon removals, especially for hard-to-abate industries.

- Recognition of the storage bottleneck: governments acknowledged the gap between available geological storage and the volumes needed for climate targets.

These commitments reinforce what the EU has already formalised through the Net-Zero Industry Act (NZIA) and the Industrial Carbon Management Strategy: Europe must expand CO₂ transport networks and deliver at least 50 Mt/year of certified storage capacity by 2030.

2. What Is CCS?

Carbon Capture and Storage (CCS) refers to technologies that:

- Capture CO₂ from industrial flue gases or directly from the air.

- Transport CO₂ through pipelines, ships or terminals.

- Store CO₂ permanently in deep geological formations.

- Optionally use CO₂ as a feedstock in fuels, materials or chemicals.

3. The CCS Value Chain Explained

3.1 Capture: The Starting Point of the CO₂ Chain

Industries can capture CO₂ using multiple technologies:

- Post-combustion (amine solvents, membranes, sorbents)

- Pre-combustion (hydrogen + CO₂ separation)

- Oxyfuel combustion

- Process capture (cement calcination, LEILAC)

- Direct Air Capture (DAC) for carbon removals

Typical capture + compression costs vary between €40–120 per tonne, depending on sector, technology and energy prices.

3.2 Transport: Pipelines, Ships and Cross-Border Corridors

Once captured, CO₂ is compressed into a dense fluid and transported via:

- Pipelines – the standard for high-volume, stable flows

- Ships – flexible transport allowing cross-border CO₂ movement

- Intermediate terminals – conditioning, buffering and scheduling CO₂ flows

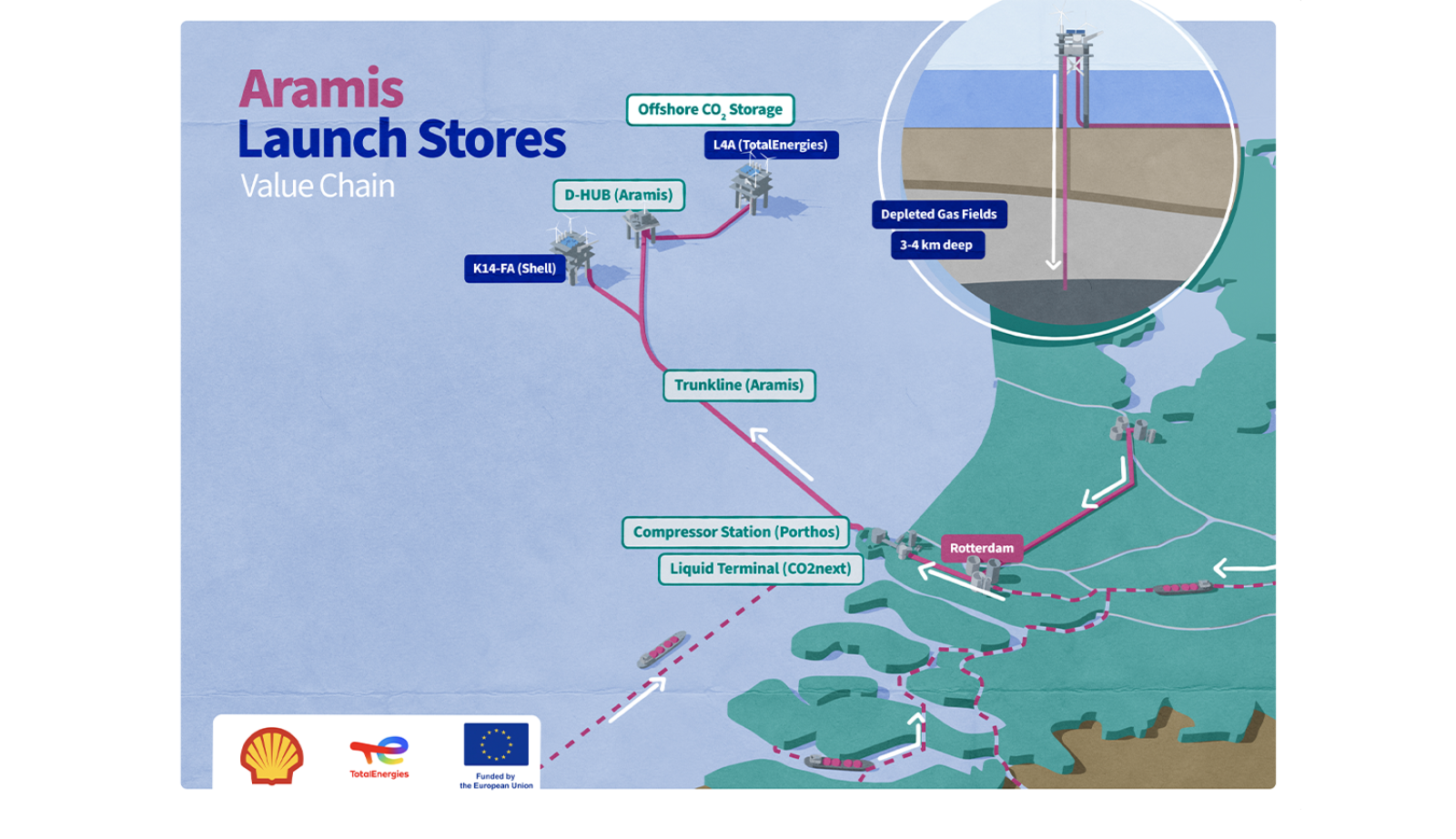

Europe’s flagship examples include Porthos, Aramis and the Northern Lights CO₂ shipping system.

3.3 Storage: Permanent Geological Containment

Permanent CO₂ storage takes place in:

- Depleted gas/oil fields

- Deep saline aquifers

- Basalt formations and mineralisation sites

Under the EU CCS Directive 2009/31/EC:

- Operators must conduct detailed site characterisation

- Long-term MMV (Monitoring, Measurement, Verification) is mandatory

- Stored CO₂ is counted as “not emitted” under the EU ETS, reducing carbon costs

- Liability transfers to the Member State only after proven stability

This regulatory foundation is a major contributor to the rapid CCS expansion in Europe.

3.4 Utilisation (CCU): Turning CO₂ into Products

Some captured CO₂ can produce:

- E-fuels and synthetic fuels

- Carbonated building materials

- Chemicals and polymers

- Greenhouse CO₂ for agriculture

Only mineralisation and CO₂ combined with permanent storage offer true long-term climate benefit.

4. The Global CCS Landscape: Key Projects and Actors

The Global CCS Institute reports:

- 77 operating CCS projects

- 47 projects under construction

- Global capture capacity surpassing 100 Mt/year once new facilities become operational

Europe’s leading developments include:

- Northern Lights (NO) – first open-access cross-border storage

- Porthos (NL) – CO₂ from Rotterdam to North Sea reservoirs

- Aramis (NL) – open-access trunkline

- Greensand (DK) – expanding Danish North Sea storage

Major technology providers include Mitsubishi Heavy Industries, Aker Carbon Capture, Carbon Clean, Fluor, Linde, Air Liquide and Svante.

NGOs and policy actors shaping CCS include Bellona Europa, CATF Europe, CCS Europe, ZEP and the Global CCS Institute.

5. Why CCS Forms a Full CO₂ Value Chain

CCS is best understood as a complex supply chain, not a single technology.

The value chain includes:

- Emission

- Capture

- Compression

- Transport

- Injection

- Monitoring & Verification

Industrial, logistics and policy actors must coordinate flows and capacities. This is why cluster-level digital twins—such as the models developed in the Act2Vision Digital Twin Studio—are critical for investment decisions, policy design and cross-border planning.

6. Key Takeaways

- COP30 reinforced global CO₂-reduction goals and the need to phase down unabated fossil fuels.

- CCS is essential for net-zero pathways in cement, steel, chemicals and waste-to-energy.

- The biggest bottleneck is storage capacity, not capture technology.

- CCS is a value chain, requiring coordination between emitters, transport operators and storage developers.

- Europe is moving fast with open-access networks like Porthos, Aramis and Northern Lights.

- Digital twins, modelling and system planning—Act2Vision’s core strengths—are becoming necessary for credible CCS cluster development.

Building process clarity today for the value chain of tomorrow.

Maarten van Oost@act2vision.nl | +31 (0) 686 698 026 | Amsterdam, Netherlands, EEA

Blogpost #1: What is CO₂ and why is it a problem and a value chain?