The product-life-cycle of a Coffee Capsule; mapping End-to-End supply chains

What is the business case for Digital Twins? This blog post describes a business case for applying the Digital Twin Breakthrough Strategy in a supply chain. An everyday recognizable product is used as an example. It demonstrates what can be done using a digital twin supply chain strategy in the pre-use phase and after product use; End-to-End. Its very likely that my ‘product of research and company’ already (partially) applied a Digital Twin Strategy in its End-to-End supply chain.

Most people appreciate a good cup of coffee!

People drink coffee in coffeeshop, bars, restaurants or at home. Maybe you have a coffee machine with coffee capsules? The coffee home culture is a trending lifestyle, an experience, with expensive, high quality, machines, which make you feel like a barrista. I like the marketing and branding campagnes providing a “feel good”, “simple to use”, “lifestyle” and “sustainable” experience.

The supply chain, Pre-, and Post-use of a coffee capsule and machine

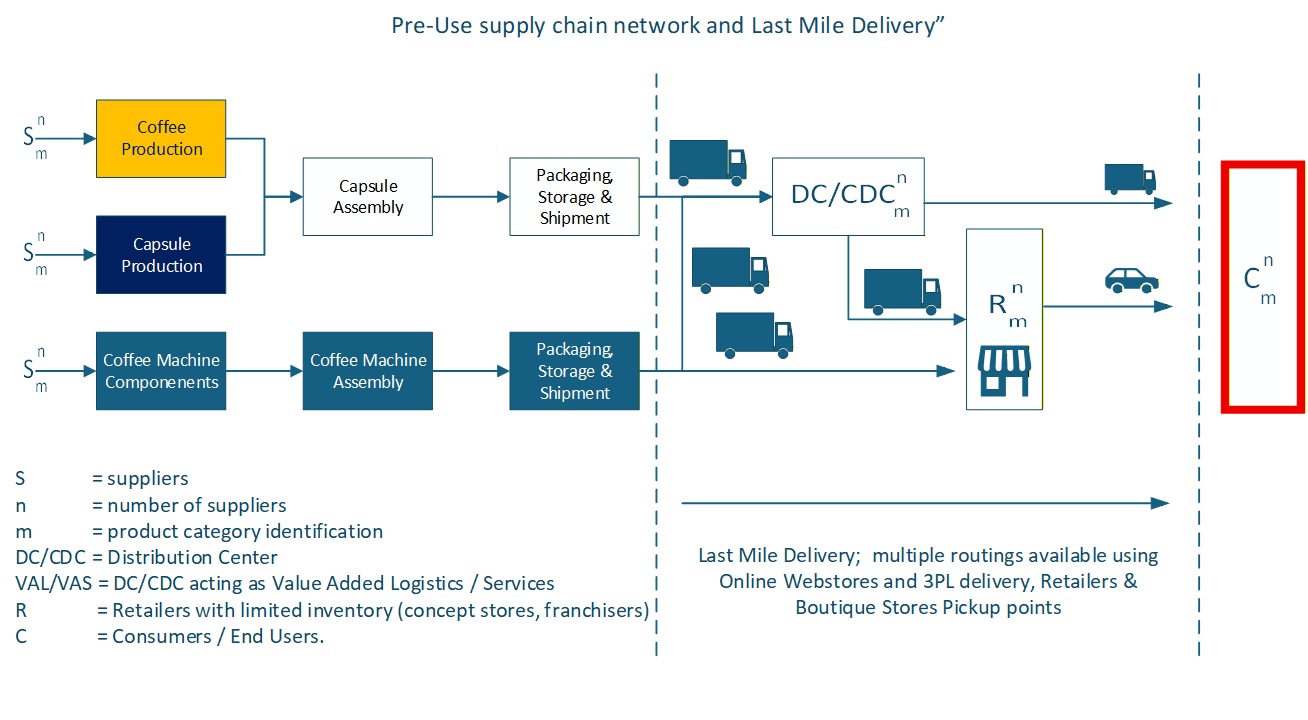

Pre-use. Your customer journey starts with marketing and sales of the Company X. Next, you buy the machine online or at a Boutique store, you choose your coffee-capsules with the taste of your personal like and your set. A fast responsive supply chain for re-ordering, loyalty programs, invoice and billing is at your convenience. And sometimes also a Post-use program, which I value as an absolute plus.

Post-use. After consumption the end-user puts the used capsule into the waste bag (either provided by the reseller of your machine and coffee capsules, or ordered at the web shop). Your full bag is picked up by the carrier or dropped at the local drop-off point. The carrier collects bags in their distribution centre to ship them frequently to the recycling centre (RC). At the RC trucks unload into the bunker from where bags are processed in the Separation Installation (SI), with shredders, separtion techniques (magnets, shakers, heaters, moisture-evaporation, gravity), connected by conveyor belts. Here life ends, closing the loop of your coffee-capsule into a one off the mono streams (aluminium, plastics, biomass and some residual. Indeed the customer life cycle experience is “feel good” and “sustainable” experience.

Costs of Pre-use and Post-use. What is the business case for Digital Twins? The coffee capsule of your choice from Company X costs about €0,20 – 0,85, depending on country of living, a post-use program, branding perceived by the customer, competition of brands available (Lavazza, Douwe Egberts, Nespresso, Illy, Starbucks, Sega Fredo), quality of coffee, and quality of materials used for the capsule (Plastics vs Aluminium). Besides the capsule, ofte you have to pay separately for delivery; costs differences again result from country and regional differences, cost of carriers, order quantity et cetera. However the costs of recycling, “feel good, easy, simple, sustainability”, are not transparant and pricing of waste disposal of the coffee capsule is included in the capsule.

Mapping End-to-End Supply Chains

What is the business case for Digital Twins? We need to understand the supply chain. So let’s break-down (Business Process Management – high level) what has to done and paid for, by the End-to-End Customer when spending €0,20 – 0,90. Without the intention of being complete I created a long list in Pre-Use (29 steps) and Post-Use (12 steps).

Coffee Capsule Pre-Use

- Farm establishment & upkeep. Payments: land lease/taxes, seedlings, shade trees, tools, irrigation, certifications (e.g., Rainforest/Organic), agronomy services.

- Cultivation (growing the coffee cherries). Payments: farm labour (planting, pruning, weeding), fertilizers/compost, pest & disease control, water, PPE, farm management software.

- Harvesting. Payments: pickers’ wages (often piece-rate), collection bags, on-farm sorting tables (risk of poor season, poor harvest). Primary processing – wet or dry. Payments: pulpers/hulling machines, water & energy, fermentation tanks, drying patios/beds/mech. dryers, parchment bags, labour, maintenance.

- On-farm QA & pre-grading. Payments: moisture meters, cupping kits, training, loss/shrink allowance.

- Local aggregation/co-op services. Payments: membership/co-op fees, storage, additional sorting, bulking, finance/advances to farmers.

6. Export preparation: Payments: milling to green, grading, defect removal, bagging (jute/GrainPro), pallets, fumigation if required, phytosanitary certificates, insurance.

7. Inland logistics to port. Payments: trucking, fuel surcharges, handling, weighbridge fees.

8. Export brokerage & documents. Payments: exporter margin, customs clearance, inspection fees, certificates of origin.

9. Ocean/air freight to importing country. Payments: freight, marine insurance, bunker/fuel surcharges, port fees.

10. Import customs & duties. Payments: tariffs (if any), VAT deferment/handling, customs broker, inspection.

11. Import warehousing of green coffee. Payments: storage, inventory financing interest, handling, sampling.

12. Roaster purchase of green coffee. Payments: green coffee price (contract or spot), quality premiums/differentials, supplier margin.

13. Roasting. Payments: energy (gas/electric), labor, depreciation on roasters, maintenance, gas abatement, waste disposal.

14. Grinding & degassing. Payments: grinders, sieving, nitrogen/CO₂ for inerting, QA lab tests, labour.

15. Aluminium (or alternative) raw material sourcing. Payments: primary/secondary aluminium, rolling into foil, lacquer/lining materials, sustainability premiums (recycled content), transport.

16. Capsule forming (empty shells & lids). Payments: forming/pressing lines, tooling, QA checks, scrap handling, labour, energy.

17. Capsule filling & sealing. Payments: filling lines, nitrogen flushing, seals/lids, in-line checkweighers/vision systems, labour, yield loss allowance.

18. Primary packaging. Payments: sachets or sleeves, cartons, inks/varnish, FSC fees if applicable, glue, packaging line time.

19. Secondary/tertiary packaging & pallets. Payments: master cases, pallets, stretch wrap/straps, labelling.

20. Brand, design, compliance. Payments: packaging design, regulatory labelling, barcodes/GS1, LCA/compliance reporting.

21. Quality assurance & certifications. Payments: lab testing (micro, O₂, shelf-life), audits, certification fees.

22. Manufacturer overheads. Payments: plant rent, utilities, admin, IT, ERP, HR, safety.

23. Marketing & trade terms: Payments: advertising, promotions, digital assets, trade spend (slotting fees, discounts), loyalty programs.

24. Distribution centre (DC) inbound. Payments: inbound transport, receiving, put-away, WMS fees.

25. DC Warehousing & inventory holding. Payments: storage, picking, cycle counts, shrink allowance, working-capital interest.

26. DC Outbound logistics to channels. Payments: line-haul to retailers, parcel/Courier for D2C, fuel surcharges, packaging for e-com shipments.

27. Retailer/e-commerce operations. Payments: retailer margin, marketplace fees, payment processing, customer service, returns handling.

28. Taxes at sale. Payments: VAT on the retail price; eco-fees where applicable (packaging EPR).

29. Consumer purchase & use. Payments by end user: €0.20–€0.90 per capsule (covers all upstream costs + margins + taxes). Also water, electricity for machine, descaler/filters, machine amortization.

Coffee Capsule Post Use

The Post-use starts the reversed logistics loop. As coffee capsules are one-time-use, it follows the Material 4th Life-cycle and transfers the capsule and its content into monostreams to be re-use in a 1-st life-cycle.

- Collection bag & label. Payments: cost of return bags, prepaid return label/answer-number postage, customer support.

- Reverse logistics pickup/drop-off. Payments: courier pickup/line-haul, retailer service point handling, consolidation to recycling hub.

- Reception & pre-treatment at recycling hub. Payments: unloading, inspection, contamination removal, batch tracking.

4. Separation: coffee grounds vs. Aluminum. Payments: shredders, mechanical/thermal separation, washing/drying, labor, energy.

5. Monostream Aluminum recycling stream. Payments: briquetting, sale to smelter/rolling mill (revenue offsets some costs), transport.

6. Coffee grounds valorization. Payments: transport to AD/composting site, gate fees (or revenue if taken as feedstock), moisture adjustment.

7. Anaerobic digestion (if chosen). Payments: digestion operations; outputs: biogas Process of selling excessive (sold to grid/ CHP (Combined Heat and Power) and digestate.

8. Composting process. Payments: windrow/aerated piles, turning, moisture/aeration control, space, compliance testing.

9. Compost curing & screening. Payments: screening equipment, Quality Control (QC), bagging (if sold), certification.

10. Compost distribution/use. Payments/revenues: logistics to farms/landscapers/municipal use; either a sale price for compost or cost-neutral application.

11. Producer responsibility & reporting. Payments: Extended Producer Responsibility fees (EPR) for packaging (country-specific), recycling scheme admin, Life Cycle Assessment/reporting (LCA), audits.

12. Corporate overhead & profit. Payments: HQ functions, finance, IT, legal, and targeted profit margins for each tier (farmer/exporter/roaster/brand/retailer).

Coffee Machine Prepare for Use and Post Use

With only coffee capsules there is no fun. We need the coffee machine. Lets map the Supply Chain and Operations of the Coffee Machine itself. The whole life cycle of this precious asset, from mining the materials until you scrap it. For the purpose of this Blog it’s not useful, still want to figure it out? Use AI generator.

“ Coffee Capsules require coffee machines. So lets break down what has to be paid End-to-End by the Customer / End User when spending €0,20 – 0,90 on a capsule. We start with the raw materials to make a coffee machine, from the origin of the materials (Mining) until the machine is scrapped and materials end op either in incineration or as monostream (materials for new purposes). List all the steps in a sequention order.”

Any idea upfront of what it takes to create a simple coffee machine for daily use?

Raw materials (mining → refined materials)

- Metals mining & beneficiation (iron ore, bauxite/aluminum, copper, nickel, tin, zinc, gold, silver, platinum-group for PCBs) → mine ops, explosives, haulage, tailings, royalties, permits.

- Smelting & refining → energy, anodes/cathodes, refining charges, emissions control.

- Polymers & elastomers → crude oil/gas extraction, monomers (ethylene, propylene, styrene), polymerization (PP/ABS/PA), compounding with pigments & flame retardants.

- Glass & ceramics (sight windows, thermostats) → silica, soda ash, kilns.

- Electronics raw materials → silicon wafers; gold/palladium/silver for finishes; cobalt, manganese, lithium (if battery/RTC present).

- Packaging basics → paper pulp (FSC), corrugate, inks, adhesives.

Material conversion → parts

- Steel/Al sheet & profile rolling; aluminum extrusion → coils, sheets, heatsinks, brackets.

- Injection molding (plastics) → housings, water tank, drip tray, capsule lever parts; toolmaking (molds), resin procurement, color masterbatch.

- Rubber/silicone molding → seals, O-rings, hoses.

- Wire drawing & cable making → copper wire, insulation, plugs.

- PCBs fabrication → laminate, etching, solder mask, surface finish (ENIG), panelization.

- Electronic components → microcontroller, sensors (NTC/flowmeter), triacs/relays, power supply, pump driver, LEDs, buttons, display, Wi-Fi/BLE (if smart).

- Electromechanical parts → pump (vibration/rotary), heater/thermoblock/boiler, flowmeter, solenoid valves, pressure relief valve, thermostats/NTC, brew head & needles.

- Surface finishing → painting, plating, anodizing, laser etching; QA.

Sub-assemblies (module build)

- Hydraulic module → pump + hoses + check valves + flowmeter + heater block + safety valve + seals.

- Brew unit → capsule piercer/holder, lever/gearbox, springs, waste bin interface.

- Power module → PSU, cordset, switch, thermal fuse, ground & insulation tests.

- Control module → PCBAs flashed with firmware, buttons/encoders, indicator LEDs.

- Chassis & enclosure → inner frame, outer covers, drip tray, cup stand, water tank.

- Aesthetics & branding → badges, panels, UI overlay, color variants.

Final assembly & factory operations

- Line assembly → pick-and-place of modules, torqueing, adhesive/clip fits.

- Functional testing → pressure, flow, temperature profile, leak test, electrical safety (hipot), standby power.

- Calibration & firmware → dosing volumes, thermistor offsets, OTA readiness.

- Quality systems → SPC, rework loop, yield loss, scrap.

- Documentation & spares → BOM, service parts provisioning, repair manuals.

- Compliance & certifications → CE/UKCA, EMC, LVD, food-contact approvals, RoHS/REACH; test lab fees, factory audits.

- Packaging → inner bags, molded pulp/foam, manuals, outer carton; labeling (barcodes, serials), palletization.

Upstream logistics & distribution

- Factory → regional DC → trucking/ocean freight, insurance, port/handling.

- Customs & duties → import tariffs, VAT deferment, broker fees.

- Warehousing → storage, inventory financing, shrink, WMS.

- Outbound to channels → retail line-haul, e-commerce parcel prep.

Commercial layer

- Brand & marketing → media, trade spend/slotting fees, content, promotions.

- Channel costs & margins → retailer margin or marketplace fees; PSP fees.

- After-sales infrastructure → call center, warranty reserve, returns policy, spare parts stocking, authorized service network onboarding.

- Producer responsibility fees (EPR/WEEE/packaging) → registration, reporting, eco-modulated fees.

- Corporate overhead & profit → SG&A, IT/ERP, finance, legal, risk, profit targets.

Point of sale (machine purchase)

- Retail price incl. VAT → customer pays; funds all upstream costs + margins + taxes.

- Extended warranty/insurance (optional) → third-party or OEM plan.

- Delivery/installation (if applicable) → fees or bundled.

In-home use phase (per-cup cost impact)

- Energy → heat-up & brew kWh; standby consumption.

- Water → municipal water per cup; optional filtration.

- Consumables (machine-side) → descaler, water filters, cleaning tablets, gasket kits.

- Maintenance → periodic descaling/clean cycles; replacement of seals, tank, drip tray.

- Repairs (out-of-warranty) → parts, labor, shipping; or replacement machine.

- Connectivity services (if smart) → app/cloud support (often embedded in price).

- Amortization of machine → the machine’s capex spread over total cups brewed (this is the hidden “machine cost per cup” that sits on top of the €0.20–€0.90 capsule spend).

Reverse logistics & service (during life)

- Spare parts distribution → pick/pack/ship to service partners or consumer.

- Returns & DOA handling → diagnostics, refurbish or scrap decisions

- Refurbish/resale loops → cleaning, repair, re-boxing (if program exists).

End-of-life (EoL) pathways

- Collection → municipal e-waste, retailer take-back, mail-back; EPR fees fund this.

- Transport to treatment → consolidation, carrier charges.

- Intake & depollution → remove hazardous parts (batteries/RTC if present), drain residual water.

- Manual dismantling (high-value parts) → PSU, pumps, heater blocks, copper wiring, PCB extraction.

- Shredding & separation → size reduction; magnetic (Fe), eddy current (Al), density/air tables (plastics), optical sort.

- Materials Recovery:

- Ferrous → steel mills.

- Aluminum → remelt.

- Copper wires → granulation/refining.

- Precious metals from PCBs → smelter (Au, Ag, Pd) recovery.

- Plastics outcome

- Mono-streams (PP/ABS/PA) to recyclers → regranulate (if clean/spec compliant).

- Mixed/contaminated plastics → incineration with energy recovery; limited mechanical recycling.

- Glass/ceramics → recycling where feasible or inert landfill.

- Residues → incineration/landfill under regulation.

- Compliance & reporting → Waste of Electrical and Electronic Equipment target attainment (WEEE), weight-based recovery/recycling rates, audits—costs borne via EPR fees embedded upstream.

Supply Chain Digital Twins Strategy

What is the business case for Digital Twins?

We did some research on the End-to-End supply chains of Drinking Coffee, mapping Coffee Machines and Coffee Capsules in Pre-Use and Post-Use. Both supply chains can be considered as complex, integrated supply chain. On every continent, in every country, through warehouses, logistics, products find their way to the customer, ending their life-cycle in mono streams. Providing customers satisfaction with global corporate responsibilities after consumption.

A real-life business case of a complex

A real-life business case of a complex, integrated supply chain, with many, many interactions, data points, decision making. How to determine the carbon footprint? How to determine Efficiency in the supply chain? What are the costs drivers in the supply chain, global, local, risk, resilience, flexibility. What are the bottlenecks in the supply chain? Where to expand? How to make growth possible in the supply chain. How to integrate supply chains in Post Use?

In previous blogposts I explained considerations before starting up a project.

- Blogpost (October 20, 2025) Data Driven Supply Chains, Digital Twin Supply Chain; elements of a Modern Supply Chain provides an introduction of Digital Twins in Supply Chain and prerequisites to start a successful implementation.

- Blogpost (October 27, 2025) Supply Chain Digital Twin Strategy (SCDTS) provides an integrated approach using AI, IoT and data analytics.

- Blogpost (November 3, 2025) Supply Chain Digital Twin Breakthrough Strategy provides a roadmap for starting up a project. Waarde Propositie en Baten.

- Blogpost (November 6, 2025) Supply Chain Digital Twin Breakthrough Strategy provides a roadmap for starting up a project – Organisatie-omvang, sectoren en investeringsomvang.

What are we actually talking about?

What is the business case for Digital Twins? Exactly, Humans (intelligence) have an idea and know how to shape and implement ideas using Artificial Intelligence (AI), by asking questions, giving assignments defining prompts, execution of commands and AI-agents finding opportunities. But AI is way more faster to execute repeatedly and learning from new Human Intelligent inputs.

Digital Twin Supply Chains is the next development (emerging) of data-driven operations. DTSC integrates real-time monitoring, analysis, and simulation to create adaptive, resilient, and efficient supply chains. In my opionion, supply chains with limited capacity (bunkers, warehouses) with frequent deliveries, aligned with production capacity (Inbound & Operations Planning & Control = Control Tower) can benefit from DTSC.

Organizations should start by developing a clear BPM foundation, invest in a standardized data infrastructure, and gradually integrate AI-driven optimization models. Starting pilot projects ensures scalability and organizational learning, paving the way for full implementation of digital twins.

Get in touch. Interested in innovations and integrated field projects for your organization? We explore, plan and implement together.

Food4TheBrAIn, Act2Vision