Warehouse operations

Warehouse operations

“if a system as a whole is to achieve its goal, it is best for the system’s individual parts to work as a team in “sync” rather than at their own individual speeds” (Balderstone & Mabin, 1998)

Warehousing cost control and optimization

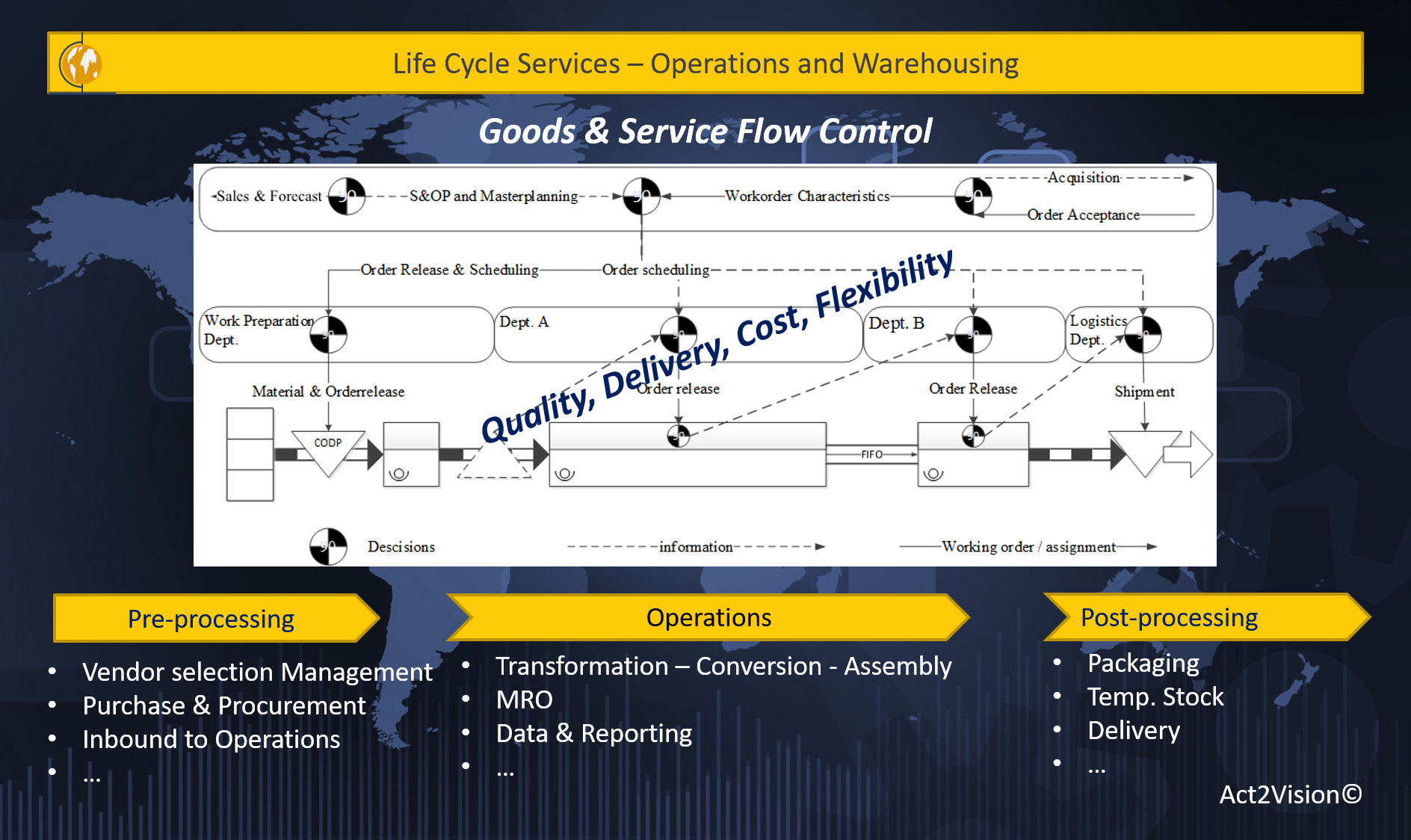

Control and Operations optimization in your warehouse (Lean, TPM)

Using a 3PL for your warehousing activities and lost the feeling of being in control? Where transportation, logistics partners- & distribution network selection is becoming more and more flexible, warehousing location decisions are still strategic and for the longer term (3 – 5 years).

A strategic consideration is whether the warehouse facility and operations should be run by the company or to outsource. Many companies take the decision to outsource there warehouse activities and handover the handling, storage and care of their product run by a 3PL. The quality of warehousing and distribution management have major impact on corporate performance and profitability.

Services:

- Warehouse 3PL auditing / locations visits and reporting

- Knowledge and experience with Excellence methodologies (Lean, TPM, Six Sigma)

- Data analysis

- Warehousing & inventory costs breakdown structure

- ABC / XYZ inventory assessment

- Benchmarking, location selection and RFP guidance

- Workflow optimization, lay-out, routing and times studies

- Planning & Visualization solutions

- Dashboard, performance monitoring

Warehousing Operations

To build responsive supply chains your warehouses, distribution centres and their performance level play a key role in fulfilment of customer demand. Still many customers provided by your warehouses are confronted with late deliveries, damaged goods, picking mistakes.

Where warehousing plays a key role in customer satisfaction, the warehouse itself is often neglected. Confronted with poor product identification, in-efficient warehousing lay-outs, lack of attention and poor management the day to day struggle for quality and delivery performance. Despite their key position, the role of warehouse operations is underestimated.

Warehouse Health Check

The Act2Vision warehouse and operations assessment is a health check of your supply chain, centred around the warehouse location(s). The check is developed for small medium sized enterprises (SME). It’s an affordable solution for SME not having the resources or opportunities to optimize warehousing operations and covers:

- Supply Chain analyses – origin … destination

- Safety and Efficiency (order handling, picking, lay-out, movement of goods and people)

- Supply and demand – product segmentation

- Product Storage – fastmovers, slowmovers, obsolete

- Suppliers & Vendor management

- Identification (products, put away locations, departments)

- Assets (people, skills, tools and equipment)

- Packaging

- Non Conformities, Deviations, Waste

- Reversed logistics, returns

- Performance Indicators

As customer intimacy, is our leading principle every request requires an unique answer. No “every dish some fish”. Based on years of experience, Act2Vision delivers.

Contact us to explore the condition of your warehouse operations.

As customer intimacy, is our leading principle every request requires an unique answer. No “every dish some fish”. Based on years of experience, Act2Vision delivers!

Consulting to expensive? Welcome in the sharing economy. We offer a high quality, flexible and affordable solution for Warehouse operations with our Service: Consulting-on-demand.